The helicopter community was shocked once again at the end of April with the crash of a CHC Super Puma just off Bergen in Norway. The Norwegian accident investigation board surprised us all again this week by releasing a second preliminary report on the accident, which not only made many in the industry saying, “not again,” but also resulted in some drastic action throughout the world. The report is as follows:

Introduction

This preliminary report is published to disseminate new and significant findings from the on-going metallurgical examinations. The report contains one safety recommendation to the European Safety Agency (EASA).

Reference is made to the AIBN preliminary report dated 13 May 2016, which was updated on 27 May (ref. Preliminary Report 27.05.2016). At that time, the AIBN considered three possible failure scenarios: Failure of epicyclic module, suspension bar (lift strut) attachment and MGB conical housing

Metallurgical Examinations Detailed metallurgical examinations have been ongoing since 19 May. Several parts from the second stage epicyclic module were retrieved from the accident site. The epicyclic module planet gears are designed as a combined gear and bearing assembly. Figure 1 shows one of eight second stage planet gears.

Planet gears have a double function, acting as a gear on the outside while at the same time functioning as the outer race of a roller bearing on the inside. In order to improve wear resistance it has been given a hard outer surface through a carburization process.

Among the recovered parts were two pieces which together form approximately half a second stage planet gear. Examinations of these parts have revealed features strongly consistent with fatigue. The fatigue appears to have its origin in the outer race of the bearing (inside of the gear), propagating towards the web of the gear teeth. There is sign of spalling in front of the fracture surface.

Although preliminary, the AIBN considers these findings to be of such significance that it has decided to issue the following safety recommendation to ensure the continuing airworthiness of the Main Gear Box (MGB).

Safety Recommendation

Recent metallurgical findings have revealed features strongly consistent with fatigue in the outer race of a second stage planet gear in the epicyclic module of the MGB. It cannot be ruled out that this signifies a possible safety issue that can affect other MGBs of the same type. The nature of the catastrophic failure of the LN-OJF main rotor system indicates that the current means to detect a failure in advance are not effective.

The AIBN therefore recommends that EASA take immediate action to ensure the safety of the Airbus Helicopters H225 Main Gear Box. The investigation is ongoing and updates will follow.

The Accident Investigation Board Norway Lillestrøm, 1 June 2016

Accidents caused by gearbox failure isn’t unique to the Super Puma, but to have this information eerily similar to the Bond helicopter crash in the North Sea in 2009, which was also caused by a similar gearbox failure followed by main rotor separation, is disturbing, and main rotor separation, is everyone’s nightmare when it comes to helicopters.

Drastic but Required Action

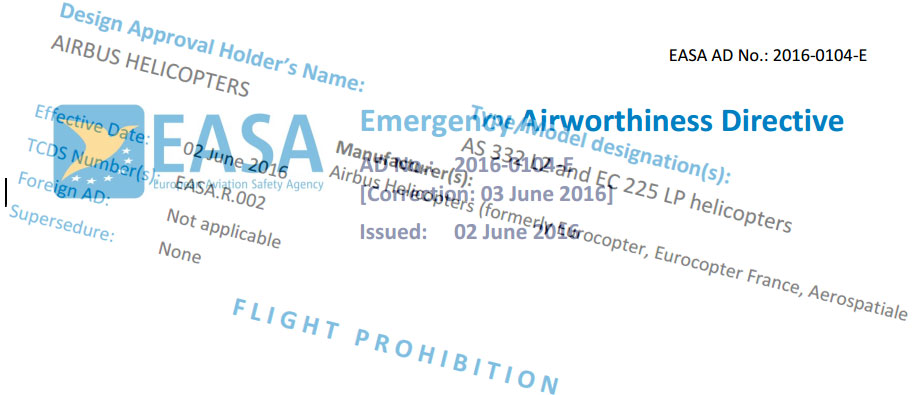

As a result of this report, EASA have issued an emergency airworthiness directive grounding all AS332 from conducting passenger service, pending further investigation into the accident and the determination of the root cause of the gearbox damage. Note that AS332 L2 and EC225 LP flights conducted by the military, customs, police, search and rescue, firefighting, coastguard or similar activities or services, may continue and are exempted from the Emergency AD.

The Emergency AD will have massive implications to the oil and gas industry worldwide as the Super Puma family forms a significant part of the industry’s workhorse fleet. Some are already calling for a redesign of the Super Puma gearbox, but whether or not that is the right thing to do at the moment is academic as we wait for the investigation to provide more information.